Construction Process of Eastern Heavy Workshop |

Eastern Heavy Machinery Co. Ltd. (Eastern Heavy) is a new joint venture company that was formed in January 2009 between two major investors, namely Weihai Huadong Automation Co. Ltd. and Schiess Brighton (Germany) Ltd. of Hong Kong, a subsidiary of Schiess Brighton Holding Ltd. registered in the Bahamas. Eastern Heavy is strategically located in Weihai City in Shandong Province on the east coast of China. The total investment in this venture is about US $ 84 million. Eastern Heavy is a high-tech company in the heavy machine tool and large component manufacturing business. The scope of the company includes research, design and the manufacture of large precision machine tools and the manufacture of large components to very demanding specifications and tolerances, for industries such as nuclear power reactors, windmills, general power generating equipment and shipbuilding, among others. Eastern Heavy is located in an industrial zone that is only three kilometers from the seaport of Weihai. The area has a solid rock base and is therefore an ideal environment for the installation of heavy machine tools and the manufacture of large precision components.

The company is situated at the tip of the eastern part of the Shandong peninsula. This location being in proximity to Japan just across the sea, and also to the Korean peninsula, the company can easily ship to these important markets, and of course to the rest of the world from this seaport location. Eastern Heavy facility sits on a property of 330,000 sq. meters (81 acres). The first construction phase will produce a manufacturing plant area of 32,000 sq/m (344,000 sq/ft) and offices and living accommodations of about 16,000 sq/m (172,000 sq/ft). The machine shop will contain ten of the Schiess Brighton ultra large machine tools, including gantry mills, vertical turning and boring mills, horizontal boring mills, horizontal lathe and a very large size gear hobber. There are three bays in the initial plant, each 300 m (984 ft.) long and 36 m (118 ft.) wide. The bays will be served by two 300 ton, one 200 ton, and one 100 ton cranes. The maximum lifting capacity will be 550 tons and the maximum height under the hook of largest cranes will be 25 m (82 ft.).

The goal of Eastern Heavy is to become one of the world’s largest machine shops for the production of nuclear power related components. The facility will contain ten of the largest machine tools of various types to provide the cutting power and precision required. More details concerning the project can be supplied in separate documentation. Eastern Heavy plans to become the major supplier of heavy components for the locally located nuclear and other industries, and those in surrounding provinces. Shandong province alone for instance is a major nuclear power source. To meet the requirements more fully, the company plans to add a heavy forging shop as soon as a suitable venture partner is identified. This will then give the facility virtually turnkey capabilities for this important industry. Schiess Brighton’s share in this effort is the design and supply of the major machine tools essential to the enterprise. These machines are a legacy of the unique position that the original Schiess AG of Dusseldorf Germany held as a supplier of huge machines for the nuclear power industry in the 1960 to 1970 decade. Schiess may have supplied as much as 95% of machines used in the heyday of nuclear power industry manufacturing. This experience in designing such machines and also the know-how involved in the machining processes required, have been inherited by the present Schiess Brighton company and have contributed to the outstanding capability of this new venture.

Construction Process of Eastern Heavy Workshop |

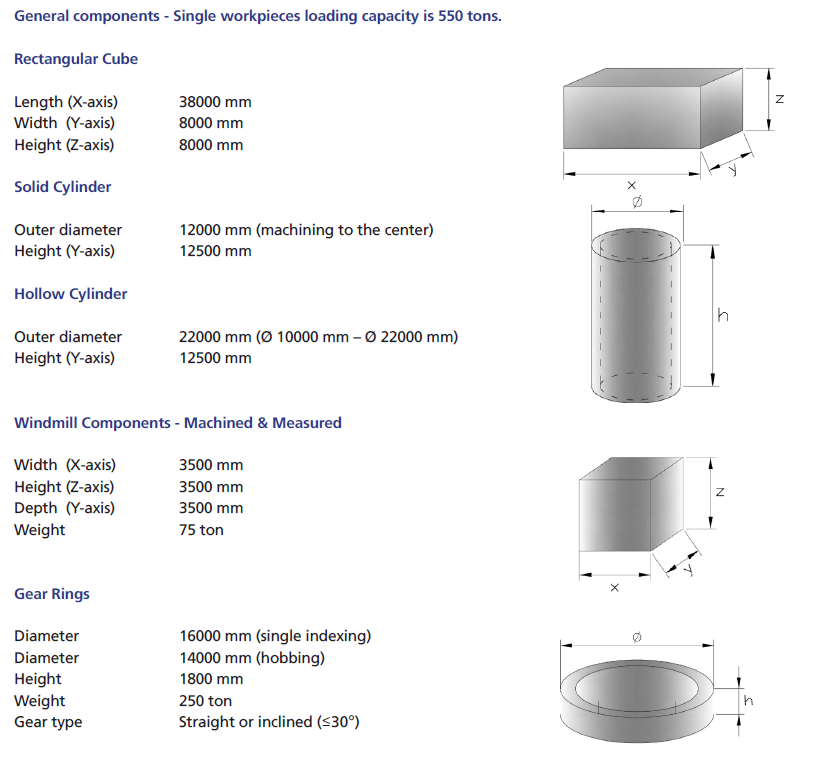

Machining Capacity Of Eastern Heavy Project |

Eastern Heavy is able to handle and machine the following workpieces to their maximum physical dimensions:-

According to the statistics of the World Nuclear Energy Association, there are 436 nuclear power plants operating worldwide as of the end of March 2009. These power plants are mainly concentrated in 5 countries: USA 114 units, France 82, Russia 48, Japan 23, and Korea 20. These plants represent about 67% of the world’s nuclear generated power or about 372 GW.

Two countries, namely China and India, will soon contribute significant numbers of nuclear generators and power. In 2009 alone, China has been building 12 plants and India has been building 6 units. It is expected that these two countries will continue to add nuclear power capacity at a rapid pace during the next 10 to 15 years. The established nuclear power countries listed above will also add about 38.8 GW or roughly 42% of all nuclear plants currently being built worldwide. By contrast, China only has seven plants operating today and these account for only 1% of the available electric power in the country.

The fastest expansion of nuclear power will take place in China in the next 10-15 years. The recently issued “New Energy Industry Expansion Plan” from the Chinese central government specifies that from 2010 to 2020, nuclear power generated should go from 10.5 GW to 86 GW. For the same period of time, it is estimated that total electricity consumption will go from 700 GW to 1200 GW. Therefore, it is planned that by 2020 nuclear power will account for about 6% of total electricitry consumption in China.

In order to achieve this ambitious goal, there 20 nuclear plants have been started in 2009 alone and it is planned to build another 65 plants in the next 11 years. In the longer run, the Chinese government has the goal to reach 16% nuclear power of total consumption by 2050.

These facts underline the enormous potential there exists in the Chinese domestic market alone for the company to become a dominant supplier to this important industry, without even considering the rapidly growing export markets.

The worldwide focus on wind driven energy is well known, and China and its eastern neighbors are no exception. China is particularly anxious to reduce its huge carbon emissions due to the widespread use of coal fired power plants; windmill technology therefore plays an important part in the future planning for the country’s power needs.

Recognizing this domestic demand and the increasing export market for windmill components, Eastern Heavy is installing a Schiess Brighton designed Flexible Manufacturing System (FMS) that will allow these machines to automatically machine virtually any components used in windmill construction to the very highest accuracy tolerances and at competitive production rates due to the very high degree of automation. The FMS system consists of various Schiess Brighton machines linked by a pallet transporter system and multiple pallet changer stations at the individual machines. These machines include the following:

4 x VERTICAL TURNING, MILLING AND BORING MACHING CENTERS Model No. VMG 40 CNC-(5-axes) Max. turning diameter 4000 mm Max. machining height 3500 mm Max. loading capacity 40 tons Special features: - Universal boring and milling ram, 52 kW power - Max. spindle rotational speed from 30 to 2500 U/min - Integrated C-axis in the table - Gantry portal moveable along table base

2 x HORIZONTAL BORING MILLS Model No. HBM 200/90 CNC-(5-axis) Max. column travel 4000 mm Max. headstock travel 3500 mm Max. headstock extension 3200 mm Max. loading capacity 75 tons Special features - Universal boring and milling head, 30 kW - Spindle rotational speed from 0 to 2000 U/min - Tiltable table for drilling hub operations

CO-ORDINATE MEASURING MACHINES X-Axis 4000 mm Y-Axis 4000 mm Z-Axis 3500 mm

PALLET TRANSPORTER About 30 exchangeable tables (pallets) Two exchangeable table positions per machine tool Automatic and programmed positionin

WASH STATION Coolant cleaning and drying Chemical treatment

Eastern Heavy is centrally and strategically located within the most active shipbuilding areas in the world, namely China, Korea, Japan, Taiwan and the rest of south East Asia. The company’s machine shops are equipped with the extremely large and powerful machine tools required by this heavy industry. The three major components that typify shipbuilding machining requirements are:

Diesel Engines This is the heart of all ships and the main component of the ships – the cylinder block requires considerable manufacturing know-how to manufacture. It requires large gantry type boring and milling machines to mill the complex surfaces and perform the precise drilling and boring operations necessary. Many operations also require horizontal boring mills with CNC rotary tables. The goal in all operations is to perform as much work in one set up as possible due to the large size and very heavy weights of the parts. Schiess Brighton gantries and boring mills are equipped with the specially designed heads and tools to achieve the maximum manufacturing efficiency.

Crankshafts These parts are turned on very large horizontal. Schiess Brighton lathes which are also equipped to perform secondary drilling and milling operations. Here again very high cutting forces and excellent surface finishes are essential for the smooth and long life operation of crankshafts.

Propeller Blades & Rudders These components posses very complex surfaces requiring 5-axes machining capabilities on large vertical turning centers and horizontal boring mills. These machines must also have very large load capacities to accommodate these ultra heavy parts. The same machines can also be used to machine so-called “Kaplan” blades for hydroelectric turbines, which have similar 5-axes contour machining requirements.

Eastern Heavy has an affiliated iron foundry in the same city, which is capable of producing single piece cast iron of up to 120 tons. The foundry operation presents as an integrated offering to the customers of Eastern Heavy. Thus, customers can order the entire machined parts.

In addition, Eastern Heavy is also capable of offering cast steel components. The cast steel components would come from one of the associated heavy machinery manufacturers in China. The single piece of cast steel workpieces is 550 tons. Subsequently, Eastern Heavy would perform the machining operations on these components according to the desires of the customers.

Eastern Heavy is affiliated with Brighton Equipment Corporation (“Brighton”), is a diversified engineering company and is a major shareholder in Schiess Brighton. Brighton specializes in the design, manufacturing and implementation of engineered projects. Specifically, Brighton is capable of and has the experience in the following heavy machinery fields

Power Plants – Responsible for designing, manufacturing and constructing of power generation plant and machinery. The sizes of the offered power plants are ranging from as small as 50 MW to as large as 1,000 MW per operating plant.

Steel Mills – Responsible for designing and supplying of steel production plant and machinery. The Company is able to offer equipment for integrated plants or mini-mills made up of EAF & LF & CCM, rolling facilities such as wire/rod and beam/section rolling mills, finishing and process systems such as galvanizing and color coating lines, etc. The offered equipment focuses in the small and medium size of steel production operations with production capacity of ranging from about 100,000 to one million ton per annum.

Cement Plants – Responsible for designing and supplying of various cement production plant and machinery. The Company offers cement mills with production capacity of ranging from 3,000 to 10,000 ton per annum.

Heavy Machinery – Responsible for designing and manufacturing of a variety of heavy machinery, such as open-die and ring forging presses, manipulators, ring rollers, etc.

The machine tools described in these pages, are the products of the Schiess Brighton partners in this venture and are all installed in the plant. They are also produced here for sale to third party customers worldwide. These machines employ the very latest design concepts and features. Despite their very large size and cutting power, they are nevertheless designed to meet the very narrow accuracy tolerances demanded by the customers they serve in the nuclear power, conventional power, aerospace, windmill and ship building industries. From these previously described ultra-large size “mother” machine tools, one can duplicate the similar range or even larger of heavy machine tools in the same categories, that are designed by Schiess Brighton, from the manufacturing facility. In addition, Eastern Heavy has an affiliated foundry factory within the same city, which is capable of producing single cast iron workpieces up to 120 tons. Thus, Schiess Brighton and Eastern Heavy jointly are able to offer any size of heavy machine tools to the customers in the world.

GANTRY BORING AND MILLING MACHINE Model No. SGM-60/90-80 XYZW-Axes 38 x 8 x 4 x 6 m Width 9000 mm Height 8000 mm Table 6000 mm Load Capacity 150 ton

SINGLE COLUMN VERTICAL BORING MILL Model No. SC-VBM 100/220-125 Table Size 10000 mm Swing 22000 mm Height 12500 mm Load Capacity 600 ton

HORIZONTAL BORING MILLS Model No. HBM 320/137 Spindle 320 mm XYZW 25 x 10 x 1.7 x 2.5 m Table Size 6000 x 6000 mm Loading 300 ton

HORIZONTAL BORING MILLS x 2 units Model No. HBM 200/90 Spindle 200 mm XYZW 20 x 5 x 1.2 x 1.7 m Table Size 2500 x 2500 mm Load Capacity 150 ton

GEAR HOBBER Model No. RF 50/140/160 Table Size 5200 mm Cutting Diameter 16000 mm Load Capacity 250 ton

DOUBLE COLUMN VERTICAL TURNING AND MILLING MILLS x 4 units Model No. VMG 40 Table Size 3500 mm Swing 4000 mm Height 3500 mm Load Capacity 75 ton

|