|

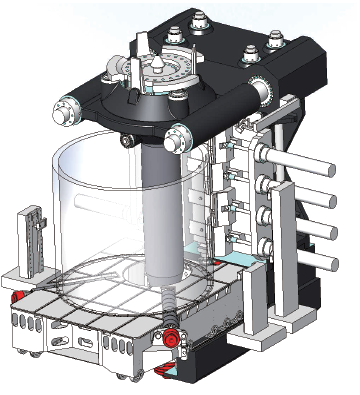

The maximum 160 MN pressing power, open-die, water and oil based hydraulic bushing forging press is applicable and specialized in large sized steel ingot forming into forged bushing. These sizable forged bushing with high grade forging quality can further be supplied to the heavy equipment manufacturing industries, such as hydro, thermal and nuclear power generating facilities, and pressure vessels for petro-chemical industry, etc.

Bushing Forging Press vs. Open-die Forging Press

The newly designed 160 MN pressing power, open-die, water and oil-based hydraulic bushing forging press would have the following advantages against the conventional hydraulic open-die forging press:

Open-die forging technology – The bushing forging press adapts the traditional open-die press forging technology; thus, the end products that the bushing press produces would be acceptable to the most demanding applications, such as nuclear power generating equipment, etc. Open-die forging technology – The bushing forging press adapts the traditional open-die press forging technology; thus, the end products that the bushing press produces would be acceptable to the most demanding applications, such as nuclear power generating equipment, etc.

Stand-alone equipment – The bushing press is a stand-alone and self-sufficient equipment. The bushing press can free up the production slots of the conventional open-die forging press, if available.

Large size bushing – By using this unique machine, one is able to produce much larger bushings than the ones from any traditional open-die forging press, which is the new challenge of the technical requirement in today’s nuclear energy industry.

Accuracy – The bushing press can produce forged bushing products more accurately than the conventional opendie forging press; thus, it would save material, machining time and overall production costs for the forged bushing products.

Efficiency – The bushing press can produce forged bushing products more efficiently than the conventional opendie forging press; specifically, the bushing press can produce anywhere from one to six forged bushing products per day, provided that there are sufficient number of furnaces to re-heat the multiple ingots in between.

Flexibility – The forging operations of the bushing forging press can be more flexible in forging operations, which can produce any desired contours by using different tooling for precision contouring shapes of the bushing or shell products. Similar to ring rolling machines, the bushing forging press will be equipped with a process control system governing each sequence of the forming process independently from the operator. This feature ensures a high quality in regards to dimensions and material structures as well as the repeatability of the whole forging process.

Technical characteristics

The design of the machinery selected all quality construction material. The machinery design used the finite element analysis method for reaching performance optimization, which resulted in the design of the hydraulic bushing forging press with rational overall frame structure, less weight. Thus, it saves overall investment.

The main body of the equipment is designed of using the pressing sleeve plug-in full stress frame structure, which would strengthen the overall rigidity of the frame of the bushing press; and it improves the tension status of the frame of the bushing press under eccentric forging.

The machine design adapted and applied special high-quality valves for the bushing press cylinder control, which resulted in the stabilization of the bushing press forging operations.

The advanced design of the hydraulic bushing forging press improved the press control accuracy by adapting the carefully selected system parts, mechanical rigidity, machine layout and automatic compensation of the bushing press dimension

Note: The first two of such machines would be operational in Erzhong, Deyang, China and Eastern Heavy, Weihai, China before the end of 2011.

|